Principles of arc welding

Arc welding is a welding process, in which heat is generated by an electric arc struck between an electrode and the work piece.

Electric arc is luminous electrical discharge between two electrodes through ionized gas.

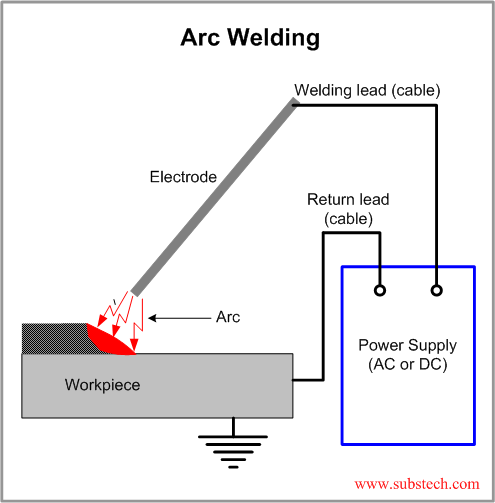

Any arc welding method is based on an electric circuit consisting of the following parts:

- Power supply (AC or DC);

- Welding electrode;

- Work piece;

- Welding leads (electric cables) connecting the electrode and work piece to the power supply.

Electric arc between the electrode and work piece closes the electric circuit. The arc temperature may reach 10000°F (5500°C), which is sufficient for fusion the work piece edges and joining them.

When a long join is required the arc is moved along the joint line. The front edge of the weld pool melts the welded surfaces when the rear edge of the weld pool solidifies forming the joint.

When a filler metal is required for better bonding, filling rod (wire) is used either as outside material fed to the arc region or as consumable welding electrode, which melts and fills the weld pool. Chemical compositions of filler metal is similar to that of work piece.

Molten metal in the weld pool is chemically active and it reacts with the surrounding atmosphere. As a result weld may be contaminated by oxide and nitride inclusions deteriorating its mechanical properties. Neutral shielding gases (argon, helium) and/or shielding fluxes are used for protection of the weld pool from atmospheric contamination. Shields are supplied to the weld zone in form of a flux coating of the electrode or in other forms.

No comments:

Post a Comment